Architectural Precast Concrete

Sidley Precast Group works directly with architects, engineers and owners to create a wide range of Architectural Precast products. With an extensive variety of aggregates, pigments and surface textures, all architectural components are custom produced to meet our customer’s exact design requirements.

- Unmatched flexibility and design control of the final form.

- Limitless finish options

- Sustainable building method that withstands the test of time.

- Sidley produces a high quality product by closely monitoring production.

- Proven economy from initial cost throughout the building life-cycle.

Structural Precast Concrete

Sidley Precast offers a wide range of structural precast components including columns, double tees, I-beams, lite walls, raker beams, seat/risers, stairs/landing and vomitory walls. These components are utilized in many commercial building structures such as airports, arenas, office and industrial structures, parking garages, schools and stadiums.

- Provides economical construction by shortened construction periods.

- Superior weathering, resists corrosion, not effected by mold, termites or dry rot.

- Low maintenance costs over the structures entire life-cycle.

- Withstands impact and abuse.

- Sidley’s forty years of expertise in the precast industry with our reputation built on honesty, integrity and quality workmanship.

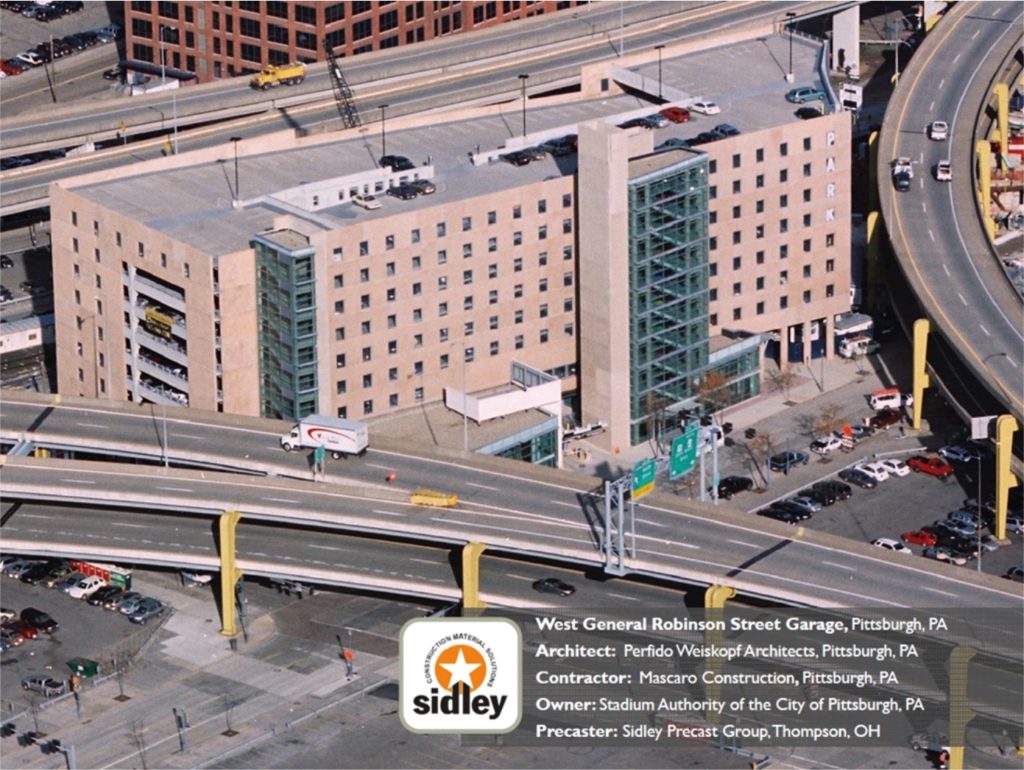

Total Precast System

Sidley Precast Group’s Total Precast System combines the advantages of architectural and structural precast into one building method that is beneficial to owners, architects and contractors. The combination of architectural exterior walls with structural precast framing can produce an open, attractive, fire resistant and economical building solution. Considering all the benefits that a Total Precast System offers, is it any wonder why it is one of the most flexible solutions for building today.

- Developers appreciate the increased speed to market allowing them to realize a quicker ROI.

- Lower insurance costs compared to other building systems

- Environmentally-friendly Green Building methods that help attain valuable LEED [Leadership in Energy & Environmental Design points.

- Large column free interior areas permitting greater design flexibility in space planning.

- Naturally fire resistant structures.

- Thermal mass of Precast helps to reduce daily temperature swings and reduces the demand on energy.

- Designers aesthetic vision can be fulfilled, since almost any architectural style imaginable can be expressed.

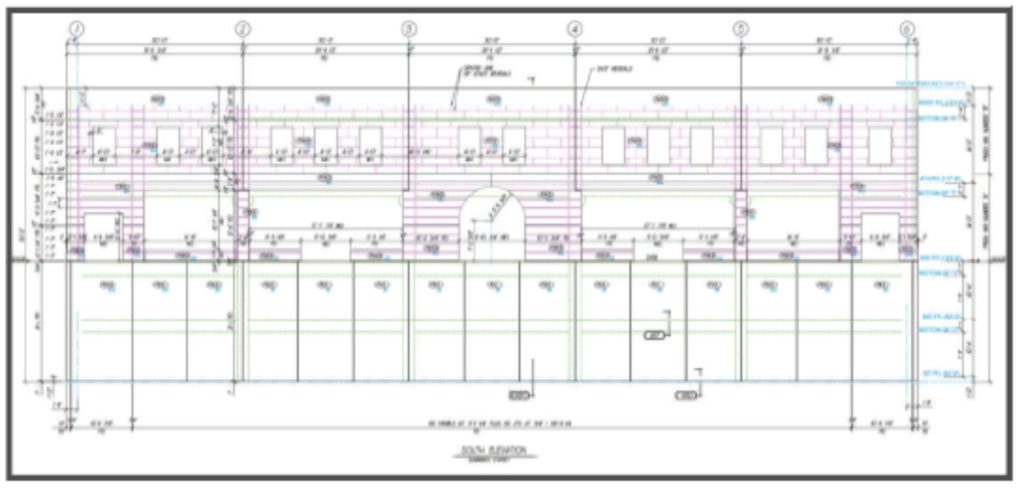

Design & Engineering

At Sidley Precast Group we take a team approach to design and work closely with our clients through the crucial design and engineering phase of projects. This permits us to assist our clients with critical decisions such as panel size, panelization of the structure, repetition of a piece to maximum economy, finish options, transportation considerations and erection issues.

- Benefit from Sidley’s years of Precast experience.

- Architects need only provide us with their intent for building loads.

- Sidley’s engineer will design all connections.

- Design-build contracts lend themselves to Precast construction.

Transportation

At Sidley we have our own fleet of specialized tractor trailers for hauling Precast which gives us complete logistical control over the delivery schedule. Our dedicated fleet is time sensitive to the scheduling demands of Precast erection and understand that time is money.

- Transportation costs maintained under same contract.

Erection

With single source responsibility all Precast work is maintained under one contract. Precast erections are completed by Sidley’s PCI Certified Erection crews. All erectors are highly skilled and experienced in the erection of Precast concrete. At Sidley’s we erect 95% of our own product. With Sidley, you have the peace of mind to know that a company with proven stability and longevity can engineer, produce and deliver product at a competitive price.

- All weather erection reduces overall construction schedule.

- Additional savings over traditional masonry which requires tenting and temporary heating in winter months.

- Faster enclosure means other trades can begin working sooner, and faster occupancy.

- Low noise levels.

- No onsite debris or waste.